How We Can Help You

At EIIG, we take a whole-of-lifecycle approach to infrastructure, delivering sustainable, environmentally conscious solutions that support both project success and long-term community benefit. From early-stage planning and smart design through construction, operation, maintenance, rehabilitation, and responsible decommissioning — we help manage every phase of the asset lifecycle.

Our teams bring expertise across a broad range of services, including survey, location, condition assessment, CCTV, non-destructive digging (NDD) proving, remediation, treatment, waste management, and resource reuse. This integrated capability allows us to deliver practical, eco-friendly outcomes that reduce environmental impact while enhancing the resilience and value of critical infrastructure.

We actively incorporate green technologies, renewable materials, and sustainable design principles to ensure our projects meet today’s needs without compromising the needs of future generations. Our deep understanding of regulatory frameworks and environmental best practices helps clients navigate complexity with confidence, achieving infrastructure that is efficient, compliant, and built to last.

Our Specialist Markets

We operate in a variety of markets, offering specialised services to address the unique challenges of each sector and ensuring that every project meets environmental standards while promoting sustainability.

Survey and Locate

How We Help

Our certified technicians use advanced equipment to locate and map both visible and hidden underground assets. This includes things like water and gas pipes, electrical and communication cables, sewer lines, and even underground voids or tanks. Knowing where these assets are can prevent accidents, avoid costly repairs, and ensure your project runs smoothly.

We use a combination of leading technologies:

- Electromagnetic Locating (EML): This technique helps us find metallic and conductive utilities, such as power cables and metal pipes.

- Ground Penetrating Radar (GPR): Useful for detecting non-metallic materials like PVC or poly piping, empty conduits, underground tanks, and even potential voids in the ground.

- Traceable Rod with EML: Allows us to trace the path of empty sewer or stormwater pipes and conduits that might not otherwise be detectable.

What You Can Expect

Once on site, our technicians will scan and map the underground layout with precision. We’ll clearly mark the ground above each identified asset and provide a detailed digital report showing exactly what was found and where. These reports are prepared in real time and sent to you directly from the field for fast decision-making.

All our locating services comply with Australian Standard AS-5488.1:2022, which governs the classification and accuracy of subsurface utility information.

CCTV Inspection

For detailed condition assessments of existing underground assets — including stormwater pipes, sewer lines, wells, shafts, and ducts — we utilise advanced Closed Circuit Television (CCTV) inspection technology. Our expert team conducts inspections and surveys in accordance with WSA 05-2008 and WSA 05-2013 standards, with all operators fully accredited to deliver reports that meet industry codes and regulatory requirements.

Our CCTV capability includes:

- Push Rod CCTV: Ideal for inspecting and locating sewer and stormwater conduits ranging from 60mm to 150mm in diameter.

- CCTV Tractor Units: Suitable for inspecting sewer and stormwater conduits from 150mm up to 2 metres in diameter, with the ability to survey up to 500 lineal metres.

- Vehicle-Mounted and Portable Systems: Flexible solutions for sites with restricted access or remote locations.

- WinCan Reporting Software: Comprehensive, high-quality inspection reports for every project.

All CCTV inspections are recorded, providing accurate documentation for maintenance planning or defect identification. Our camera systems are equipped with high-powered sondes, which, when used alongside our advanced locating equipment, enable precise pinpointing of defects or areas requiring further investigation.

With pan, tilt, and zoom functionality, our CCTV technology allows for detailed inspection of even the smallest imperfections across extensive underground networks, ensuring reliable and actionable data for asset owners and project stakeholders.

Pipeline Rehabilitation

Damaged pipes don’t always mean disruptive excavation. We offer a smarter, no-dig solution with the Quick-Lock system — a trenchless pipe repair technology designed to restore the integrity of sewer and stormwater pipelines without digging up roads or property.

Quick-Lock uses a combination of self-locking V4A stainless steel sleeves and seamless EPDM rubber gaskets to seal and reinforce pipes ranging from 150mm to 800mm in diameter. This innovative method provides a fast, clean, and long-lasting repair — ideal for a wide range of common pipeline defects.

Why Choose Quick-Lock?

- No excavation required – Repairs are made from inside the pipe, minimising disruption to surrounding surfaces

- Fast installation – Most sleeves are installed in minutes with minimal site setup or traffic control

- Structurally sound – Reinforces the pipe and seals defects with a 50-year life expectancy

- Low-risk and cost-effective – Reduces labour, downtime, and reinstatement costs

- Environmentally friendly – No need for excavation or pipe replacement

Certified & Approved

- RMS approved for stormwater and drainage repairs

- WSAA appraised for sewer and water asset owners

- Jetting resistant, tested to DIN-19523 standards

- Backed by a 50-year manufacturer warranty

Why It Matters:

Quick-Lock is the efficient, proven solution for maintaining pipeline performance and extending asset life — without the mess and cost of traditional excavation.

Pipe problems? Fix them fast, from the inside out.

Non-Destructive Excavation (NDD)

When you need to dig with precision and safety, non-destructive excavation services offer the smarter, safer solution. Our modern fleet of vacuum excavation trucks — ranging from agile 4×4 units to powerful combination drain cleaning trucks (4,000 to 8,000 litres capacity) — is equipped to handle projects of all sizes across urban, industrial, and remote sites.

Using a combination of high-pressure water or air and a powerful vacuum system, we expose underground utilities without damaging them or their protective coatings. This process is ideal for projects like road and civil works, power and light pole installations, tree planting, and safely uncovering buried services before any ground disturbance occurs.

Why Choose Non-Destructive Digging?

- Minimises surface damage, reducing reinstatement and clean-up costs

- Protects underground assets, eliminating the risk of utility damage

- Fast and cost-effective, delivering precise results without heavy machinery

- Safe material disposal, with soil and debris contained in vacuum tanks and disposed of at approved facilities

- Improves on-site safety, reducing manual handling and injury risk

- Environmentally responsible, with a lighter footprint than traditional digging

Our Capabilities

- Our trucks are equipped to perform a wide range of excavation techniques:

- Hydro Vacuum Excavation – Combines high-pressure water and suction to quickly and cleanly expose utilities with pinpoint accuracy.

- Air Excavation and Knifing – Uses compressed air to loosen soil without water, perfect for dry sites or where water use must be limited.

- Vacuum (Suction) Excavation – Efficiently removes dry or wet materials, ideal for clearing around sensitive infrastructure or transferring debris from hard-to-access areas.

Why It Matters:

With NDD services, you reduce risk, improve efficiency, and protect what’s underground — all while staying compliant and environmentally conscious.

Dig smarter. Dig safer.

Environmental Remediation

We deliver services aimed at restoring and rehabilitating contaminated sites, promoting environmental sustainability, circular economy and compliance. We emphasise continuous improvement in sustainable practices, maintaining current industry and EHP regulatory licences that undergo periodic audits, providing full-cycle environmental solutions without compromising quality, all while adhering to strict regulatory waste elimination and reuse principles. Our ISO certifications include validation that sustainability is at the core of everything we do.

Waste Management

Blocked or silted pipes can cause costly delays, environmental hazards, and structural damage. We operate a modern fleet of high-velocity drain cleaning trucks designed to efficiently clear stormwater and sewer lines ranging from 150mm to 1800mm in diameter.

Our combination jetting and vacuum trucks use powerful 1” water jetting pumps (up to 333L/min at 170 bar pressure) and extended 180m hoses to dislodge and remove debris, roots, fats, and other blockages. With onboard 6,000L debris tanks, we safely capture and dispose of waste, keeping your site clean and operational.

Comprehensive Drain Maintenance

To support our cleaning services, EIIG integrates CCTV pipe inspection to verify blockage removal and assess pipe condition. This allows us to accurately plan future maintenance and minimise unplanned downtime across your site.

Our Services Include:

- Jet cleaning of sewer and stormwater drains

- Clearing culverts and flood-prone pipelines

- Removal of silt, blockages, roots, and debris

- CCTV inspection and condition reporting

- Reservoir and pump station cleaning

- Gross pollutant trap and tank cleaning

- Waste transport and disposal to licensed facilities

Why It Matters:

Whether it’s routine maintenance or emergency response, EIIG ensures your pipe and drainage systems stay clear, compliant, and operational — with minimal disruption.

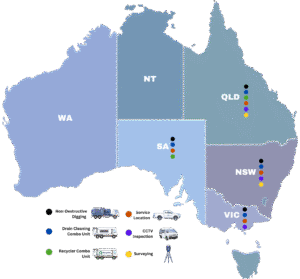

Locations